6/3/15 - Fail on MOT Emissions

Had yearly MOT today. FAILED! A few simple points like rear fog lights. On major failure was the emissions. CO % Fail and Lambda Fail. CO was 0.435% Lambda was 1.807 at Fast 2500-3000rpm

Initial thoughts where the Lambda sensor. Replaced Lambda sensor. Found the old one was very black with soot. Indicates Running Rich (as does the CO readings being well out) The problem is that the Lambda is showing it really lean.

Retested and still the same High CO and High Lambda. How can I have an engine which is Rich & Lean. Too much Fuel & Too much air!

8/3/15 - Retest

Anyway manged to get it through MOT after a long warm up and pressing the emissions test at the right place so I have a years ticket but still have issues.

Still CO & Lambda where way over but having a Fast at 4250-4850 rpm bought the levels down if we pressed the test button at the right time.

I have also noticed that the fuel consumption is higher & exhaust (lambda sensor & tail pipe have black soot)

Investigations / Cause:

OK so I have a number of things which can cause High CO and High Lambda:

Found this table:

(Legend: L = Low, H = High , M = Moderate)

| CO | CO2 | HC | O2 | Possible Problems |

H

|

L

|

H

|

H

| Rich mixture with ignition misfire |

H

|

L

|

H

|

L

| Faulty thermostat or coolant sensor |

L

|

L

|

L

|

H

| Exhaust leak after the converter |

L

|

H

|

L

|

H

| Injector misfire, catalytic converter operating |

H

|

L

|

ML

|

H

| Rich mixture |

H

|

H

|

H

|

H

| Injector misfire, catalytic converter not working; combination of rich mixture and vacuum leak |

L

|

L

|

H

|

H

| Ignition misfire; lean condition; vacuum or air leak between air flow sensor and throttle body (false air) |

L

| H |

L

|

L

| Good combustion efficiency and catalytic converter action |

L

| |

L

|

L

| All systems operating within tolerance; normal reading |

The following table lists some of the results possible when the AFR (air-fuel ratio) is sustained at conditions ranging from too lean to too rich.

| Conditions | Results |

| Too Lean | Poor engine power

Misfiring at cruise speeds

Burned valves

Burned pistons

Scored cylinders

Spark knock or ping |

| Slightly Lean | High gas mileage

Low exhaust emissions

Reduced engine power

Slight tendency to knock or ping |

| Stoichiometric | Best all-around performance |

| Slightly Rich | Maximum engine power

Higher emissions

Higher fuel consumption

Lower tendency to knock or ping |

| Too Rich | Poor fuel mileage

Misfiring

Increased air pollution

Oil contamination

Black exhaust |

So from this information I think it could be the following:

- Fault Code on ECU

- CAT Not working

- Exhaust Blockage / Restricted / Leaking

- MAP Sensor

- Coolant Sensor (Oil Temperature)

- Dirty Injectors / Stuck Fuel Injector

- Fuel Pressure Regulator / Too High Fuel Pressure

- Blocked Air filter

- Faulty Lambda Sensor

- Faulty PCV Breather

- Tappet Adjustment

- Faulty Charcoal Valve

So in order to diagnose I thought I would take my time and not rush out and buy expensive parts. I have done the following investigations.

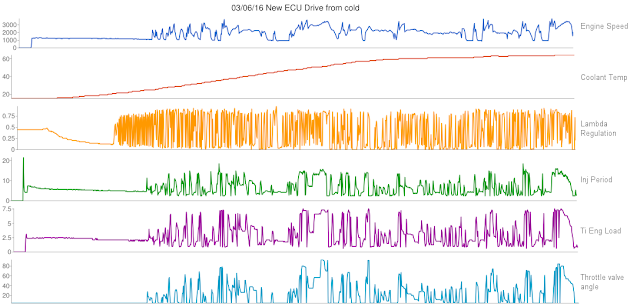

1. Fault Code on ECU - Check ECU and only one fault code which my van has had ever since I purchased it - Throttle Valve position - I think this is just the Zero setting for throttle body when installed. I ran VCDS and logged the data and compared it with a log I ran a year before. Could not see any differences.

Still to test -

Find out how to reset throttle position to clear fault code for ever. Need to get the correct process in VCDS and try setting.

2. CAT Not working

Could be a blocked or non functioning Catalytic convertor - These are £600 to £469 which is the cheapest in the UK. They ONLY COST £60 in Brazil!

My main concern in replacing the CAT is that the Lambda sesnor was covered with soot & carbon so unless its blocked (causing blow back) it is rich from the engine pre-cat as the lambda is the last sensor. CAT function is hard to test.

Still to test -

Measure CAT function - Temp before and after CAT.

3. Exhaust Blockage / Restricted / Leaking

A block or restricted exhaust causes issues. It basically causes the exhaust to recirculate in the combustion and even inlet manifolds. This could be the cause but ran a vacuum test on the inlet (common and useful technique for Air leaks and back pressure) this showed a typical "normal" response.

Leaking exhaust can cause issues but I cannot find any leaks or holes. Exhaust is expensive to replace so will leave this until later.

Still to test -

Will try the rag up the exhaust to see if it stalls and what it looks like with a restricted exhaust.

Will remove CAT & Both boxes and have a look for blockages. Need to order gaskets, new bolts & exhaust sealant

4. MAP Sensor

MAP sensor is the prime sensor for the amount of fuel to inject into the engine. If it was reading an incorrect level it "could" be the reason to run too rich. No fault codes so in range but could be giving a false reading.

I don't have the VCDS version with MAP pressure readings but plan to check against gauge.

I have been looking for the MAP sensor. Parts from Bosch are typically around £100 so not going replace this unless I am sure.

Still to test -

Measure pressure with gauge and check MAP output voltage with voltmeter.

Purchase VCDS to get access to Measurement blocks 0000 which has MAP pressure readings

5. Coolant Sensor (Oil Temperature)

The engine runs rich until up to temperature. So if faulty will constant run in open loop and rich.

Checked with Multimeter and also Logged data with VCDS and its seems to be correct values and heats up to switch to closed loop once warm. No fault codes. So not coolant sensor at fault.

One thing to note is that the oil temp takes ages to switch to closed loop (approx 80oC) short journeys could be causing to run rich for ages. I am sure the hotter climate in Brazil it does not take so long. On UK days takes a far few miles to get to 80oC.

Still to test -

Check coolant vs temp response.

Maybe include an extra resistance to make value read 10oC hotter so goes into closed loop earlier (great for shorter journeys)

6. Dirty Injectors / Stuck Fuel Injector

If an injector gets stuck on. The engine will over fuel and run rich. The engine will sense this at lambda and I would expect the on pulse duration to be very short as the engine tries to lean out. I did not see this on the VCDS logs.

Used carb cleaner on inlet throttle body and down to injectors. Also added a bottle of Redex injector cleaner.

Still to Test -

Test using a fuel pressure gauge (should stay at pressure for long time when pump is off - leaky injector will cause rapid pressure decay) need to restrict fuel back to pump

To test I will need to check the spray pattern (remove and spray into a jar)

7. Fuel Pressure Regulator / Too High Fuel Pressure

If the fuel pressure is too great (pump) or faulty fuel pressure regulator causing too higher pressure. This will cause the injector to over fuel so the ECU thinks its pulsed the correct amount but mixture is too rich so will back off pulse duration to lean out mixture.

I have check the pulse widths from a good emissions run done last year and after emissions failure and they seem the same nothing indicates an issue. However I have been reading about short term and long term trims. This should show if its and issue BUT I cannot find them in the VCDS log.

Checked the vacuum line to the pressure regulator for fuel (indicates a leaking regulator seal) and found none so suspect its good

Still to Test -

Test using a fuel pressure gauge not sure what the actual fuel pressure should be but expect regulator should return pressure back to fuel tank.

Replace fuel filter and see if its causing a higher pressure. Blocked filter will cause higher pressure but reduced flow.

8. Blocked Air filter

Block air filter will cause lack of air and therefore rich mixture. Inspected the air filter and looks clean.

Still to Test -

Will replace air filter as part of next service

9. Faulty Lambda Sensor

Faulty Lambda sensor will cause over or under fueling. The ECU should report a fault code if lambda is at fault.Replaced the Lambda sensor anyway, so its not the sensor.

Still to Test -

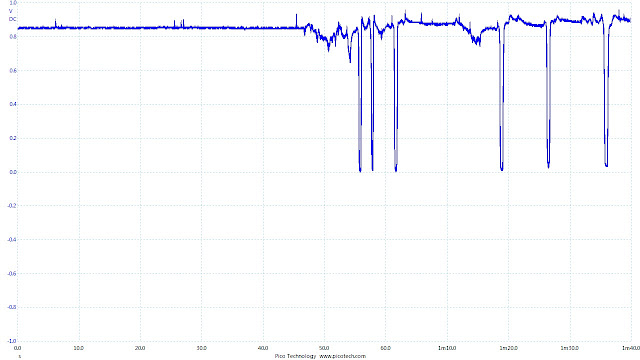

Will check with scope the Lambda signal and see if the ECU is getting a lean or rich mixture from its voltage response.

10. Faulty PCV Breather

I have noticed from the HC levels of zero this could indicate a blocked or non functional crankcase breather valve.

I have noticed before that the breather does not seem to be working and pipes are always blocked with the "gunk" " Mayonnaise" from the oil / water mix. This is common place with air cooled engines and short journeys never burning off the water.

I have no managed to source a new PCV valve (211 129 101) took me ages to find one finally got one from The Netherlands.

When fitting it I noticed that all the other Brazilian engines had the breather fitted vertically. Mine was always fitted horizontally and therefore incorrect.

Now fitted a new one the right way round! Not much difference but I am sure its better and working now. Not sure what effect it will have on emissions.

11. Tappet Adjustment

The tappets will have an effect on emissions. So reset and they did not make any difference to emissions.

12. Charcoal Valve

The engine uses the fuel tank breather re-circulation via a charcoal canister and valve. This then adds an extra breather fuel back to be burnt. This is regulated via the ECU once the engine is warmed up.

This could cause an extra over fueling and rich mixture if always on. The VCDS logs show that this is functioning BUT a faulty valve could cause this to be always on but this should be measured at Lambda sensor and adjusted for

Still to Test -

Test the canister valve to see if it functions on demand.

So in summary I have done the following:

- New Lambda Sensor

- Carb Cleaner / Redex

- New & correct fitting PCV Valve

- Replaced Vacuum hoses

- Measured Inlet Manifold Vacuum - Looks normal no leak or restriction

- Tappet Adjustment

- Measured coolant, throttle, injector, valves etc nominal resistance - All within specifications

I have to do the following:

- Clear fault code from ECU (TPS zero offset)

- Test for blocked CAT - Block exhaust check Vacuum / Remove inspect

- Measure CAT temperatures

- Test Coolant Sensor - Resistance Vs Temp

- Measure MAP Sensor Response - VCDS & Output Vs vacuum gauge

- Fuel Pressure - Leaky / Stuck injector / Fuel Filter replace

- Measure Lambda response

- Test Charcoal valve - Power & Check